NAWCAD’s Auditory Performance Lab Collaborating with Navy Dentistry to Improve Hearing Protection - Featured in Naval Aviation Enterprise

The Naval Air Warfare Center Aircraft Division (NAWCAD) has partnered with Navy Dentistry to modernize hearing protection for sailors and warfighters using digital ear-scanning and 3D printing technology. Recognizing that noise-induced hearing loss remains the Defense Department’s most common injury, NAWCAD’s Auditory Performance Lab, led by LCDR Kyle Shepard, has developed a faster, safer, and more precise way to create custom-fit hearing protection.

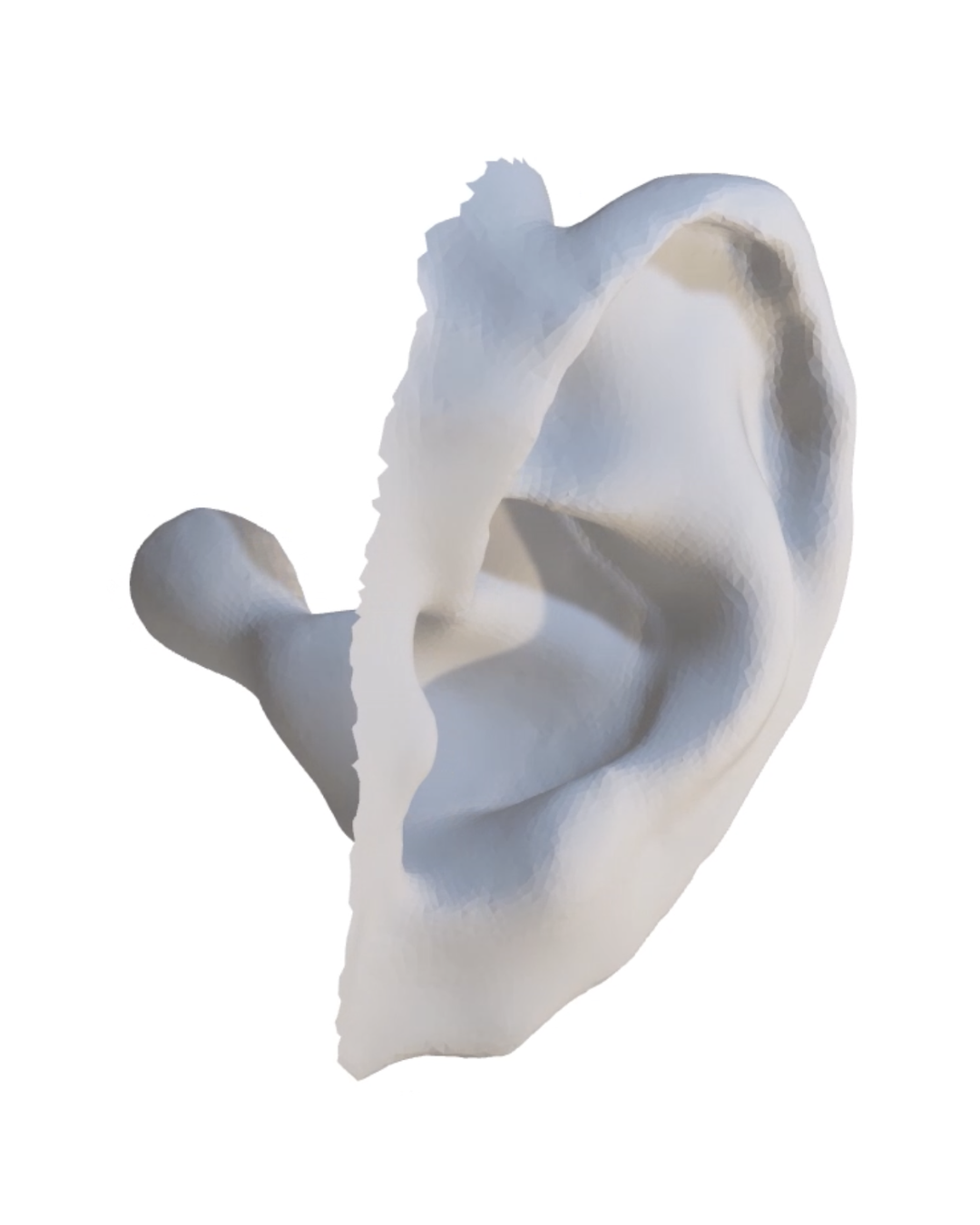

Traditional silicone-impression methods are slow, inconsistent, and can cause discomfort or anatomical complications. In contrast, digital ear-scanning captures the exact geometry of a sailor’s ear canal using a small probe, eliminating the risk of physical warping and reducing production time by over 50 percent. This innovation—aligned with the Navy’s existing 3D printing infrastructure in dental medicine—allows commands to manufacture custom earplugs on-site, ensuring improved comfort, reliability, and protection.

Early fleet testing shows overwhelming support from sailors and Marines, who report superior fit, comfort, and communication clarity compared with foam or standard plugs. The program’s ultimate goal is to equip every service member with custom hearing protection made from precise 3D ear scans, enhancing safety, readiness, and mission performance across the Department of Defense.